|

Product Details:

|

| Product Name: | Purlin Roll Forming Machine | Cutting Length Accuracy: | ±1mm |

|---|---|---|---|

| Control System: | PLC | Roller Stations: | 18 Stations |

| Power: | 22KW | Material Thickness: | 1.0-3.0mm |

| Roller Material: | Cr12, Heat Treatment | Cutting Type: | Hydraulic Cutting |

| Highlight: | High Precision Purlin Roll Forming Machine,Purlin Roll Forming Machine 11KW | ||

High-Accuracy Purlin Roll Forming Machine for Automatically Size Changing

Purlin Roll Forming Machine is a high-precision machine for producing purlin with high efficiency. It is equipped with a powerful 11KW motor and 15 stations roller. The roller is made of Cr12 steel with heat treatment, ensuring strength and stability. The machine is equipped with a hydraulic punching system and a hydraulic cutting system for fast and precise cutting. Furthermore, it is integrated with a PLC control system for accurate and efficient operation. With its reliable and precise performance, this machine is an ideal choice for purlin production.

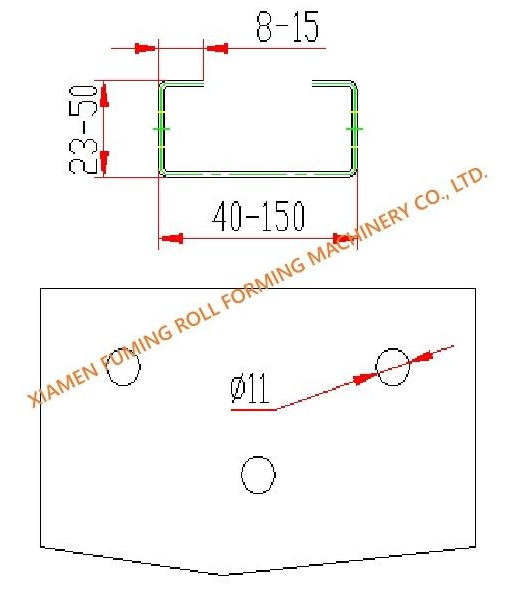

Drawing:

| ROLL FORMING MACHINE FOR C PURLIN | |

| Material Specification | |

| Thickness | 0.9mm to 1.75mm |

| Material | GI |

| Yield strength | 235MPa or customized |

| Machine Components | |

| 1.5T*300mm Simple Decoiler | |

| Unpower, Load capacity | Max.1.5Tons |

| Coil Inner-diameter | 510±30mm |

| Coil width | Max.300mm |

| Coil outer-diameter | Max.1200mm |

| Pre-leveling Device | |

| Pre-Level Device with 5 shafts to remove the Coil-set, Manual control | |

| Hydraulic Pre-punching and Pre-notching device | |

| Punching tool material | Cr12, heat treatment |

| Hydraulic pump motor | 11KW(sharing with Hydraulic Non-Stop Cutting device ) |

| Roll Forming Machine | |

| Driving system | Gear/sprocket |

| Forming station | 15 stations |

| Roller material | Cr12, heat treatment |

| Shafts Diameter | Φ60mm |

| Main motor | 11KW, frequency speed control |

| Line speed of rollformer | Approx. 25m/min or customized |

| Motor for size changing | 1.5KW*1+0.75KW*2 |

| Hydraulic Non-Stop Cutting device | |

| Cutting type | Non-stop cut, no blanking cut |

| Positioning | By pneumatic pin |

| Cutting tool material | Cr12, heat treatment |

| Photoelectric induction switch | To ensure the distance between the edge to the first hole is fixed |

| Hydraulci pump motor | 11KW |

| PLC Control System | |

| Function | Control quantity and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider or Delta |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±2 mm or customized |

| Control Voltage | 24V |

| Product Rack | Un-powered, 3meters*2 |

The Purlin Roll Forming Machine from XIAMEN FUMING is an indispensable tool for any construction project. It is made in CHINA and comes with a minimum order quantity of 1. The price is negotiable and the packaging is without outer packing, shipped by container. The roller material is Cr12 with heat treatment, and the material thickness is between 0.9-1.75mm. It is designed for forming C purlin, and uses hydraulic punching and hydraulic cutting with 15 stations of rollers.

Technical Support and Service for Purlin Roll Forming Machine

We provide comprehensive technical support and service for Purlin Roll Forming Machine. Our team of experienced engineers and technicians can help you achieve optimal usage of the machine and maximize its performance.

If you have any questions or need technical support for Purlin Roll Forming Machine, please don't hesitate to contact us. We are here to help you.

Technical Support and Service for Our Machines

We provide comprehensive technical support and service for our machines. Our team of experienced engineers and technicians can help you achieve optimal usage of the machine and maximize its performance.

If you have any questions or need technical support for our machines, please don't hesitate to contact us. We are here to help you.

.jpg)

.jpg)

.jpg)

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram