|

Product Details:

|

| Roller Stations: | 10 Stations | Roller Material: | 45# Steel, Hard Chorme Coated |

|---|---|---|---|

| Material Thickness: | 1.0mm | Product Name: | Racking System Roll Forming Machine |

| Motor Power: | 4KW | Forming Speed: | 12600 Pieces Per Day (16 Hours, Two Shifts) |

| Material Type: | Galvanized Steel | Control System: | PLC |

| Highlight: | H50 Bar Roll Forming Machine,Bar Roll Forming Machine 4KW,Z Bar Steel Roll Forming Machine | ||

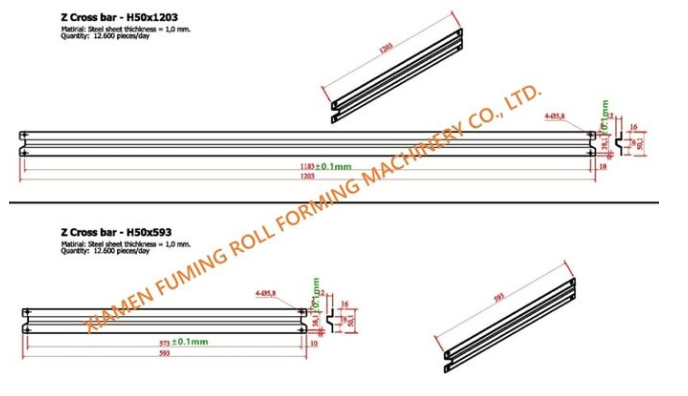

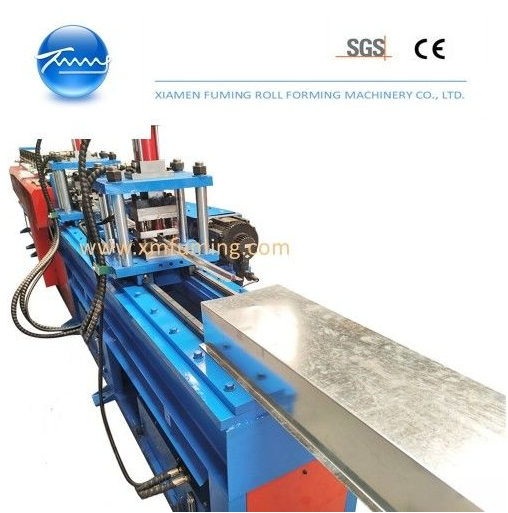

Z Cross Bar Roll Forming Machine for H50 Profile

Z Cross Bar Roll Forming Machine is a kind of machine specially used in producing H50 profile. It uses rollers to form the material into pre-determined shapes. The forming speed of this machine is 12600 pieces per day , with cutting length tolerance of ±1mm, and the material thickness can be adjusted up to 1.0mm. It is equipped with a PLC control system and hydraulic cutting system, ensuring high accuracy and reliability of the products.

Drawing:

| ROLL FORMING MACHINE FOR Z CROSS BAR H50 PROFILE | |

| Material Specification | |

| Thickness | 1.0mm |

| Yield strength | 250MPa |

| Machine Components | |

| 1.5Ton*300mm Simple Decoiler | |

| Load capacity | Max.1.5Tons |

| Coil inner-diameter | 510±30mm |

| Coil outer-diameter | Max.1200mm |

| Coil width | Max.300mm |

| Roll Forming Machine | |

| Driving system | Gear/sprocket |

| Forming station | 10 stages |

| Roller material | 45# steel, hard chorme coated |

| Shafts Diameter | Φ60mm |

| Servo motor to drive | 4KW |

| Production speed | 12600 pieces per day (16 hours, two shifts) |

| Non-Stop Hydraulic Post Punching & Post Cutting Device | |

| 1st hydraulic cylinder | To punch |

| 2nd hydraulic cylinder | To punch and cut |

| Cutting type | Slug breaker |

| Punching mould material | Cr12, Heat treatment |

| Cutting mould material | Cr12, Heat treatment |

| Hydraulic station | 4KW |

| PLC Control System | |

| Function | Control quantity, punching and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±1 mm |

| Control Voltage | 24V |

| Product Rack | Un-powered, 3 meters long |

XIAMEN FUMING's Z Cross Bar Roll Forming Machine is specially designed and manufactured for H50 production. With galvanized steel as the material, this machine is able to make the material thickness of 1.0mm. It is featured with PLC control system, and the cutting length tolerance is ±1mm, which ensures high precision. The price is negotiable and the machine is shipped without outer packing, shipped by container.

We provide technical support and service for Roll Forming Machine, including:

Q 1: How can customers be assured that XIAMEN FUMING will deliver qualified roll forming machines?

A 1: Customers can send their technician or entrust a third party to XIAMEN FUMING’s factory to do machine inspection before delivery.

XIAMEN FUMING can send their engineers to the buyer’s factory for machine installation and commissioning.

Our roll forming machine is guaranteed for one year in correct operation and maintenance.

Q 2: How does the customer install the machine when it arrives?

A 2: Our engineers will go to your factory for machine installation and commissioning once you get your machine ready(including electricity, testing material, hydraulic oil, auxiliary staff, transport and lifting device, etc.), they will instruct your technician how to operate the machine. Online supports including video call will be provided if our engineers cannot visit your place because of pandemic.

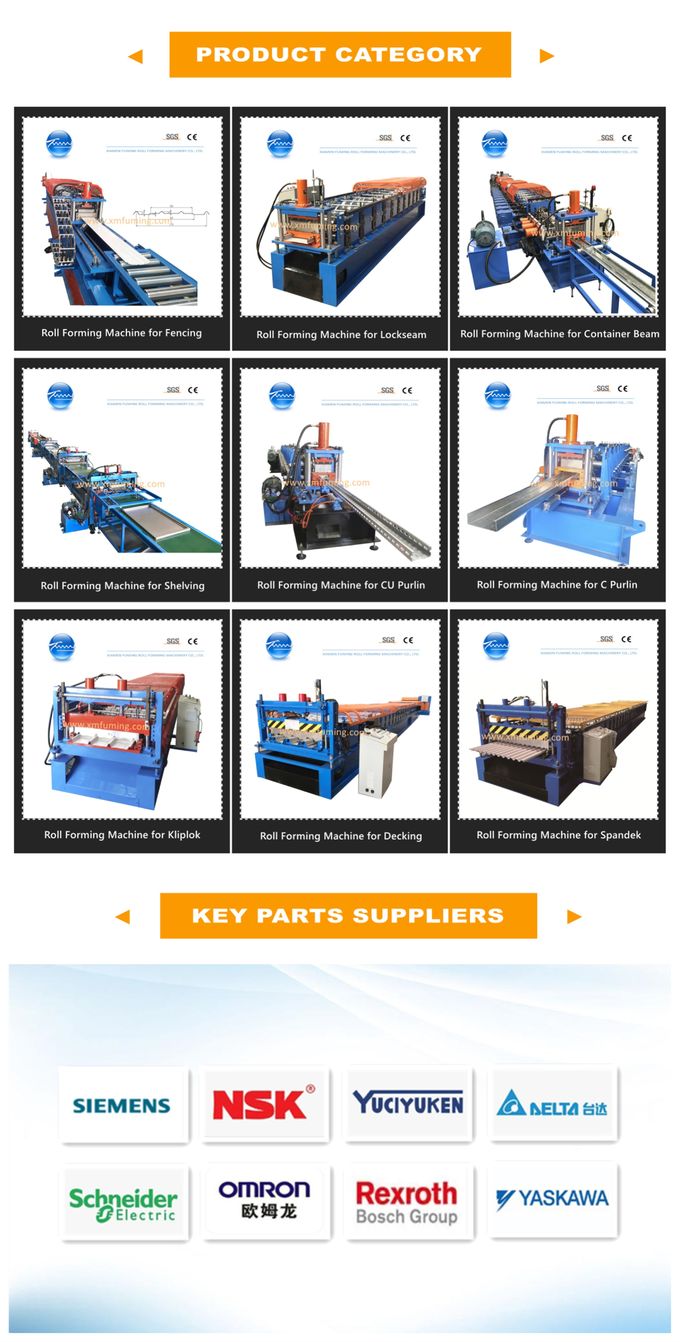

Q 3: Does XIAMEN FUMING provide customized roll forming machines?

A 3: Yes, we design and make roll forming machines according to the latest market trend and the specific requirements suggested by customers.

.jpg)

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram