|

Product Details:

|

| Cutting Tolerance: | ±2mm | Cutting Type: | Hydraulic Cutting |

|---|---|---|---|

| Product Name: | Roofing Truss/Batten/Top Hat Roll Forming Machine | Transmission: | Gear/sprocket |

| Roller Stations: | 10 Stations | Forming Speed: | 18m/min |

| Roller Material: | 45# Steel, Hard Chrome Coated | Material: | GI |

| Highlight: | Profile Top Hat Roll Forming Machine,Top Hat Roll Forming Machine Custom | ||

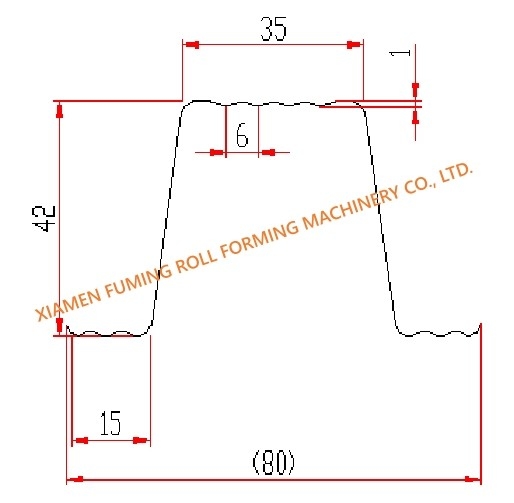

Top Hat Roll Forming Machine for YX42-80 Profile

| ROLL FORMING MACHINE FOR ROOFING TRUSS/BATTEN PROFILE | |

| Material Specification | |

| Thickness | 0.5mm to 0.6mm |

| Feeding width | Approx.148mm |

| Material | GI, PPGI |

| Yield strength | 250MPa or customized |

| Machine Components | |

| 1.5Ton*300mm Simple Decoiler | |

| Load capacity | Max.1.5Tons |

| Coil inner-diameter | 400-580mm |

| Coil outer-diameter | Max.1600mm |

| Coil width | Max.300mm |

| Roll Forming Machine | |

| Driving system | Gear/sprocket |

| Option for driving system | Gear box or toroidal worm box |

| Forming station | 8 stations |

| 5 rollers shaping device | 1 unit |

| Roller material | 45# steel, hard chorme coated |

| Option for roller material | Cr12, Cr12Mov |

| Shafts Diameter | Φ60mm |

| Main motor | 3KW, frequency speed control |

| Line speed of rollformer | Approx. 15m/min or customized |

| Hydraulic Cutting Device | |

| Cutting type | No blanking cut |

| Cutting tool material | Cr12, heat treatment |

| Hydraulci pump motor | 3KW |

| PLC Control System | |

| Function | Control quantity and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider or Delta |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±2 mm or customized |

| Control Voltage | 24V |

| Product Rack | 2 meters×2 |

Are you in search of a roofing truss/batten/top hat roll forming machine that can meet your requirements? Look no further than the one from XIAMEN FUMING. This roll forming machine is the ideal choice for producing high speed and high-precision roofing truss/batten/top hat.

Technical Support and Service for Roofing Truss/Batten/Top Hat Roll Forming Machine

We provide comprehensive technical support and service for Roofing Truss/Batten/Top Hat Roll Forming Machine. Our team of experienced engineers and technicians can help you achieve optimal usage of the machine and maximize its performance.

If you have any questions or need technical support for Roofing Truss/Batten/Top Hat Roll Forming Machine, please don't hesitate to contact us. We are here to help you.

Q 1: How can customers be assured that XIAMEN FUMING will deliver qualified roll forming machines?

A 1: Customers can send their technician or entrust a third party to XIAMEN FUMING’s factory to do machine inspection before delivery.

XIAMEN FUMING can send their engineers to the buyer’s factory for machine installation and commissioning.

Our roll forming machine is guaranteed for one year in correct operation and maintenance.

Q 2: How does the customer install the machine when it arrives?

A 2: Our engineers will go to your factory for machine installation and commissioning once you get your machine ready(including electricity, testing material, hydraulic oil, auxiliary staff, transport and lifting device, etc.), they will instruct your technician how to operate the machine. Online supports including video call will be provided if our engineers cannot visit your place because of pandemic.

Q 3: Does XIAMEN FUMING provide customized roll forming machines?

A 3: Yes, we design and make roll forming machines according to the latest market trend and the specific requirements suggested by customers.

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram