|

Product Details:

|

| Material: | PPGI | Power: | 3KW |

|---|---|---|---|

| Control System: | Electric Control | Model: | YX12 |

| Forming Speed: | 15m/min | ||

| Highlight: | Rib Sandwich Panel Roll Forming Machine,3KW Sandwich Panel Roll Forming Machine,Rib Roll Forming Machine | ||

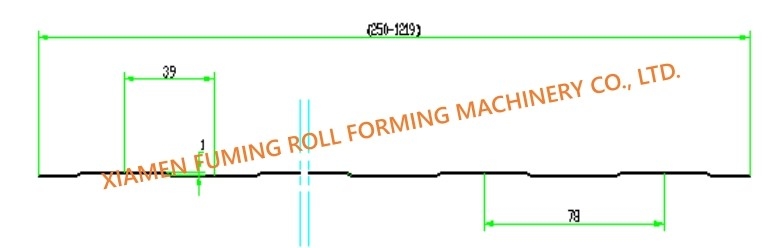

Rib Forming Machine for YX12 Sandwich Panel Profile

The Rib Forming Machine is ideal for producing ribs for sandwich panels with stable performance.

Drawing:

| RIB FORMING MACHINE FOR YX12 SANDWICH PANEL PROFILE | |

| Material Specification | |

| Thickness | 0.5mm to 0.6mm |

| Effective width | 260 to 1180mm |

| Feeding width | Approx.1250mm |

| Material | PPGI |

| Yield strength | 250MPa |

| Machine Components | |

| 5Ton*1250mm Hydraulic Decoiler | |

| Coil inner hole expanding | Hydraulic system, 3KW pump motor |

| Speed regulating | Frequency inverter, 3KW motor |

| Expanding type | Taper wedge expanding system |

| Load capacity | Max.5Tons |

| Coil inner diameter | 510±30mm |

| Coil outer diameter | Max.1600mm |

| Coil width | Max.1250mm |

| Stop/start rotation | Automatic stopping device with limited switch to assist |

| Hydraulic Pre-shearing Device | |

| Function of pre-shearing devic | Smart cut control, to cut off the end of the final piece of sheet only |

| Cutting blade material | Cr12, heat treatment |

| Hydraulci pump motor | 3KW |

| Rib Forming Device | |

| Rib forming rollers | 1 set |

| Shaft Diameter | Φ65mm |

| Motor | 3KW |

| Electric Control Box | |

| Function | Control stop, forward, backward |

.jpg)

XIAMEN FUMING Rib Forming Machine for Sandwich Panel Profile, model number YX12, is a reliable and cost-effective equipment. The voltage of the equipment can be customized.

We provide comprehensive support for Rib Forming Machine for Sandwich Panel Profile, including:

Our team of experienced professionals will work with you to ensure your Sandwich Panel Roll Forming Machine is running efficiently and reliably.

If you have any questions or require support for your Rib Forming Machine for Sandwich Panel Profile, please contact us.

Q 1: How can customers be assured that XIAMEN FUMING will deliver qualified roll forming machines?

A 1: Customers can send their technician or entrust a third party to XIAMEN FUMING’s factory to do machine inspection before delivery.

XIAMEN FUMING can send their engineers to the buyer’s factory for machine installation and commissioning.

Our roll forming machine is guaranteed for one year in correct operation and maintenance.

Q 2: How does the customer install the machine when it arrives?

A 2: Our engineers will go to your factory for machine installation and commissioning once you get your machine ready(including electricity, testing material, hydraulic oil, auxiliary staff, transport and lifting device, etc.), they will instruct your technician how to operate the machine. Online supports including video call will be provided if our engineers cannot visit your place because of pandemic.

Q 3: Does XIAMEN FUMING provide customized roll forming machines?

A 3: Yes, we design and make roll forming machines according to the latest market trend and the specific requirements suggested by customers.

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram