|

Product Details:

|

| Roller Material: | Cr12, Heat Treatment | Roller Stations: | 20 Stations |

|---|---|---|---|

| Main Motor Power: | 18.5KW | Cutting Tolerance: | ±2mm |

| Product Name: | Door Rail Roll Forming Machine | Material Thickness: | 2.0mm |

| Control System: | PLC Control | Cutting Method: | Hydraulic Cutting |

| Feeding Width: | 210mm | Speed: | 20m/min |

| Highlight: | Profile Door Rail Roll Forming Machine,Door Rail Roll Forming Machine 18.5KW | ||

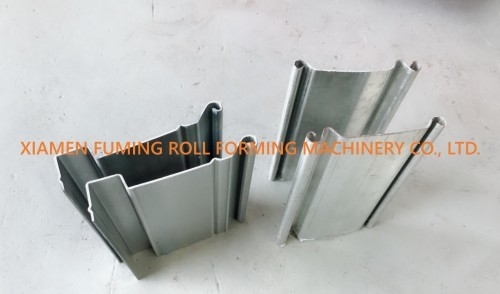

Door Rail Roll Forming Machine

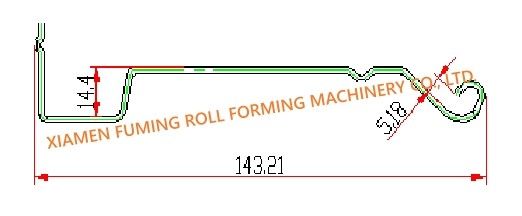

With easy-to-operate technology, this powerful shutter door bottom plate roll forming machine can make shutter door bottom plate with a cutting tolerance of ±2mm and speed up to 15m/min, making it the good choice for mass production. The machine is also equipped with PLC control system, providing greater accuracy and stability while producing the shutter door bottom plate.

| ROLL FORMING MACHINE FOR SHUTTER DOOR BOTTOM PLATE | |

| Material Specification | |

| Thickness | 1.5mm to 1.8mm |

| Feeding width | Approx.213mm |

| Material | GI |

| Yield strength | 250MPa or customized |

| Machine Components | |

| 1.5Ton*300mm Simple Decoiler | |

| Load capacity | Max.1.5Tons |

| Coil inner-diameter | 400-580mm |

| Coil outer-diameter | Max.1600mm |

| Coil width | Max.300mm |

| Option | Please refer to decoiler on home page |

| Roll Forming Machine | |

| Driving system | Gear/sprocket |

| Option for driving system | Gear box or toroidal worm box |

| Forming station | 16 stations |

| 5 rollers shaping device | 1 unit |

| Roller material | Cr12, heat treatment |

| Option for roller material | Cr12Mov |

| Shafts Diameter | Φ75mm |

| Main motor | 11KW, frequency speed control |

| Line speed of rollformer | Approx. 15m/min or customized |

| Cooling System | |

| Circulation of cooling water | By water pump |

| Injecting nozzle | Above the rollers |

| Water collecting | By quadrate flume fixed on the base-frame |

| Bringing back the cooling fluid | By blowing pipe cauda |

| Daily clean | Special design for tank |

| Hydraulic Cutting Device | |

| Cutting type | Slug breaker |

| Cutting tool material | Cr12, heat treatment |

| Hydraulci pump motor | 7.5KW |

| PLC Control System | |

| Function | Control quantity and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider or Delta |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±2 mm or customized |

| Control Voltage | 24V |

| Product Rack | Un-powered, 4 meters |

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram