|

Product Details:

|

| Transmission: | Gear/sprocket | Roller Material: | 45# Steel, Hard Chrome Coated |

|---|---|---|---|

| Material: | GI | Power: | 5.5KW |

| Control System: | PLC Control | Forming Speed: | 15m/min |

| Cutting Type: | Hydraulic Cutting | ||

| Highlight: | Profile Custom Roll Forming Machine,Custom Roll Forming Machine Precision,Plate Profile Roll Forming Machine | ||

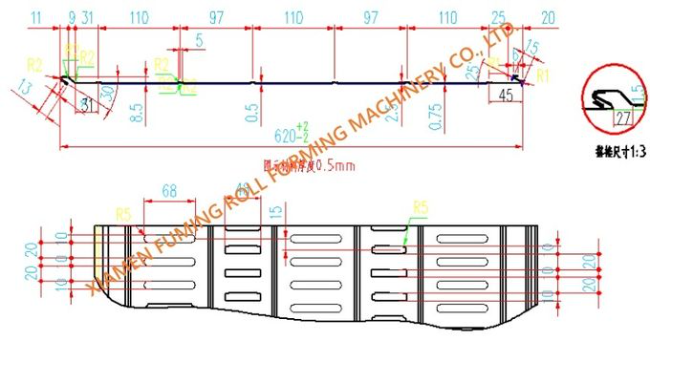

Roll Forming Machine for YX8.5-620 Truss Plate Profile

The Truss Plate Roll Forming Machine is designed to meet the high performance requirements. It adopts the PLC control system, transmission with gear/sprocket, and has a high precision cutting length. This Truss Plate Roll Forming Machine is ideal for producing truss plate with high accuracy, high efficiency and stable performance. With a wide range of applications, it is an ideal choice for truss plate forming operation. Its advanced technology ensures a reliable, efficient and safe operation in various environments.

Drawing:

| Roll Forming Machine For YX8.5-620 Truss Plate Profile | |

| Material Specification | |

| Thickness | 0.4mm to 0.8mm |

| Effective width | 620mm |

| Feeding width | Approx.660mm |

| Material | PPGI |

| Yield strength | 250MPa |

| Machine Components | |

| Roll Forming Machine | |

| Driving system | Gear/sprocket |

| Option for driving system | Gear box or toroidal worm box |

| Forming station | 10 stations |

| Roller material | 45# steel, CNC lathes, hard chrome coated |

| Option for roller material | Cr12, Cr12Mov |

| Shafts Diameter | Φ65mm |

| Main motor | 5.5KW, frequency speed control |

| Line speed of rollformer | Approx. 15m/min or customized |

| Hydraulic Cutting Device | |

| Cutting type | Slug breaker |

| Cutting tool material | Cr12, heat treatment |

| Hydraulci pump motor | 3KW |

| PLC Control System | |

| Function | Control quantity and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider or Delta |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±2 mm |

| Control Voltage | 24V |

| Product Rack | Un-powered, three units |

.jpg)

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram