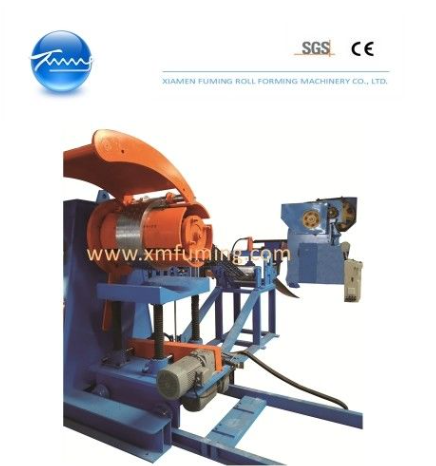

In the metal fabrication industry, precision, efficiency, and customization are key to meeting diverse production needs. Among the most essential tools in this field is the GI custom roll forming machine with perforation line, a highly specialized system that allows for continuous shaping, punching, and recoiling of metal strips into finished profiles.

At the forefront of this innovation stands FUMING, a leading GI roll forming machine manufacturer based in China, known for delivering high-performance, custom-engineered roll forming solutions tailored to the unique requirements of global clients. As a trusted custom perforation line supplier, FUMING offers integrated systems that combine forming, punching, and recoiling — including models equipped with a 5.5kW recoiling line for metal strips — ensuring seamless operation and superior output quality.

The Role of Custom Roll Forming Technology

Roll forming is a continuous bending operation used to shape metal coils or strips into desired cross-sectional profiles. It is widely applied in the manufacturing of structural components, building materials, automotive parts, and industrial equipment.

When enhanced with a perforation line, these machines can also perform precise punching or hole-making during the forming process — ideal for creating ventilation panels, fencing, shelving, and other products requiring both structure and design elements.

The integration of a 5.5kW recoiling line for metal strips further enhances productivity by enabling automatic collection of formed material, reducing manual labor, and improving workflow consistency.

This level of automation and precision makes GI custom roll forming machines with perforation lines indispensable in modern metalworking facilities.

Why Choose FUMING?

As a China-based manufacturer, FUMING combines decades of engineering expertise with state-of-the-art production facilities to develop advanced roll forming systems that deliver unmatched performance and reliability. With a strong focus on R&D and client-specific needs, FUMING has earned a solid reputation among metal fabricators, construction companies, and OEMs around the world.

What sets FUMING apart is its ability to offer fully custom roll forming solutions. Whether you need a single-purpose machine or a multi-functional system with integrated punching, cutting, and recoiling capabilities, FUMING works closely with clients to design and build equipment tailored to their exact specifications.

This includes options such as variable speed control, PLC touch screen interfaces, servo-driven feeding systems, and modular tooling setups — all designed to maximize flexibility and ease of use.

High-Quality Engineering for Industrial Demands

Each GI roll forming machine produced by FUMING is built using premium-grade steel components and precision-machined rollers, ensuring long-term durability and consistent performance even under heavy-duty conditions.

The custom perforation line is equipped with high-speed punching units capable of producing clean, accurate holes in various patterns and sizes, adjustable according to product design.

Additionally, the 5.5kW recoiling line for metal strips ensures smooth and stable take-up of the formed material, preventing tension damage and maintaining product integrity. This system supports a wide range of strip widths and thicknesses, making it suitable for both thin-gauge and heavy-duty applications.

All FUMING machines are tested rigorously before delivery and come with CE certification, guaranteeing compliance with international safety and operational standards.

Supporting Global Clients with Custom Solutions

From architectural panel production to HVAC duct manufacturing and agricultural equipment assembly, FUMING’s GI custom roll forming machines with perforation line are versatile enough to support a broad spectrum of industries.

As a professional custom perforation line supplier, FUMING provides end-to-end support — including technical consultation, layout planning, installation guidance, and after-sales service — ensuring that every client receives a complete and optimized solution.

Whether you're setting up a new production line or upgrading an existing one, FUMING offers scalable configurations that adapt to your capacity and output goals. Their team of engineers works directly with clients to understand workflow dynamics and recommend the most efficient machine setup for optimal results.

In the competitive landscape of metal processing and manufacturing, having a reliable and adaptable roll forming system is crucial. FUMING delivers exactly that — combining cutting-edge technology, expert craftsmanship, and custom engineering to meet the evolving needs of global industries.

As a China-based GI roll forming machine manufacturer, FUMING continues to push the boundaries of innovation by offering advanced, user-friendly systems that enhance productivity and reduce downtime. Whether you're looking for a standard model or a fully custom-built solution with integrated perforation line and 5.5kW recoiling line for metal strips, FUMING provides the quality, performance, and support needed to succeed — one profile at a time.

Contact Person: Mrs. Shelby Chen

Tel: +86 18205983863

Fax: 86-592-6290-260

Skype

Telegram